Senator Joe Donnelly's Office Visits Crossroads Industrial Services

On Tuesday, September 8th, Crossroads Industrial Services hosted Brandon Herget, Senator Joe Donnelly’s Indiana Regional Office Director for a plant tour of our east side manufacturing facility. This was the second opportunity Herget had to visit Crossroads Industrial Services within the last few years to witness the great things that happen at Crossroads Industrial Services every day.

Herget had the opportunity to check in on long-standing contract manufacturing jobs at Crossroads Industrial Services such as corrugated containers that are assembled for Harlan Labs and EPS recycling that is provided for several Indiana companies like Walmart, Roche Diagnostics and Stanley. He also was able to see new opportunities started since his last visit with companies like Gimme Charge, in which Crossroads manufactures a golf cart USB charging system and CareCycle, in which we recycle plastic filters used in hospital surgery rooms.

Pictured from left to right are: Greg Roberts – Product Manager, Katy Stafford-Cunningham – VP Public Policy/INARF, Brandon Herget – Regional Director for Senator Joe Donnelly, Sarah Chestnut – Public Policy Coordinator/INARF, and Anne Traub – Human Resources Manager.

Greg Roberts – Product Manager and Brandon Herget – Regional Director for Senator Joe Donnelly

On a personal level, Herget was able to talk with several employees about their work at Crossroads Industrial Services and how employment opportunities had benefitted them. He discussed with several employees the critical role that IndyGo has played in their daily commute to and from work. Currently, more than 50% of Crossroads Industrial Services employees use either the fixed route bus service or the para-transit door-to-door service.

Senator Donnelly has been a great supporter of creating opportunities for individuals with special needs to thrive in the workplace. Senator Donnelly is included as one of our nation’s Senators and Representatives that have earned the distinction of being named a Source America Champion. Source America is an organization that was created thru legislation in the early 1970’s to help create workplace opportunities for individuals with special needs. Crossroads Industrial Services is a proud member of Source America, primarily through our work in manufacturing Combat Identification Panels for the US Army and USMC.

State Representative Donna Schaibley Visits Crossroads Industrial Services

As part of our ongoing initiative to invite Indiana State Representatives, Senators and Congressmen to Crossroads Industrial Services, a Division of Easter Seals Crossroads, to inform and engage their support for increasing business development and more employment for persons with disabilities, we had a visit from State Representative Donna Schaibley, District 24, on Thursday, September 3rd. Rep. Schaibley learned about our business at a Carmel Rotary Club meeting in August where Curtiss Quirin, COO of Crossroads Industrial Services, was giving a business presentation on manufacturing solutions. As a result, she asked if she could visit us to see what great things we’re doing at Crossroads Industrial Services. Rep. Schaibley was very interested in the numerous jobs that we provide for persons with disabilities through our contract manufacturing services, document services, and order fulfillment services, just to name a few. She was also able to speak with several of our employees and saw what a great job they were doing.

Pictured from left to right are: Anne Traub – Human Resources Manager, Indiana State Rep. Donna Schaibley, and Curtiss Quirin – COO of Crossroads Industrial Services.

Pictured from left to right are: Rep. Donna Schaibley, Curtiss Quirin, and Tyler Wagner, employee

Rep. Donna Schaibley and Claire Strahan, employee

We really appreciated Rep. Schaibley’s interest and enthusiasm for what we do at Crossroads Industrial Services and she will prove to be a great advocate in the Indiana House of Representatives for supporting more employment for persons with disabilities.

Product Launch – Real Food Blends

When starting anything new, and especially when launching a new product, it is always beneficial to begin with the end in mind. Planning is key and there are many tools and checklists available. An effective way to alleviate some of the stress related to launching a new product is to work with a contract manufacturer, like Crossroads Industrial Services.

Real Food Blends partnered with Crossroads Industrial Services to help provide quality service to its customers. Julie and Tony Bombacino started Real Food Blends in 2012 with the desire to provide 100% real food to be used via feeding tubes. Inspired by the need to supply their son AJ with quality food, Julie researched feeding-tube alternatives and began blending real foods when AJ was 10 months old.

View and listen to their story here:

When we first met the folks at Crossroads Industrial Services (CIS), we knew right away that we wanted to partner with them. The amazing work they do to employ and empower people with disabilities is amazing and inspirational. As parents of our own special needs son (AJ), my wife (co-founder and CEO of Real Food Blends) Julie Bombacino and I are proud to work with the team at CIS. It’s been really rewarding and easy to work with them to date and we look forward to partnering more in the future as we continue to grow Real Food Blends.

– Tony Bombacino, Co-Founder & CMO, Real Food Blends

A contract manufacturer, like Crossroads Industrial Services, can help speed up your new product launch and reduce startup expenses by providing you with manufacturing resources on a variable basis.

You Get What You Inspect

Today’s post was written by Curtiss Quirin, Chief Operating Officer of Crossroads Industrial Services.

I learned a long time ago, you don’t get what you expect, you get what you inspect. This concept is very simple to grasp, but very difficult to implement and sustain. Inspection requires not only the creation of a standard, but also the discipline to observe and audit on a regular basis. If done correctly it will help to create constancy of purpose and the development of a work culture.

How many times have you personally or your company started a new initiative (sometimes with great fanfare), only to see it slip away over time? This generally occurs because the expectation was created, but no follow up was established. This confuses your work force and makes people skeptical of any future changes. That is why before any new initiatives are started, you, as the leader, must decide what is important and be prepared to stay the course. The goal is to set a standard and change behavior.

The following are the key steps required to get started:

- Pick something important

- Involve your people

- Establish measurable requirements

- Make it visible

- Set up an audit frequency

- Have the discipline to stay the course

People will do what is important to them and what they perceive is important to you, but if you ask an employee to do something and never come around to check to see how it is going or whether it was even done, you are sending a very confusing message. So before you begin a new initiative, develop your plan on how you will audit the activity.

Crossroads Industrial Services instills these values in our employees and production managers. Learn more about our unique workforce on our employees page.

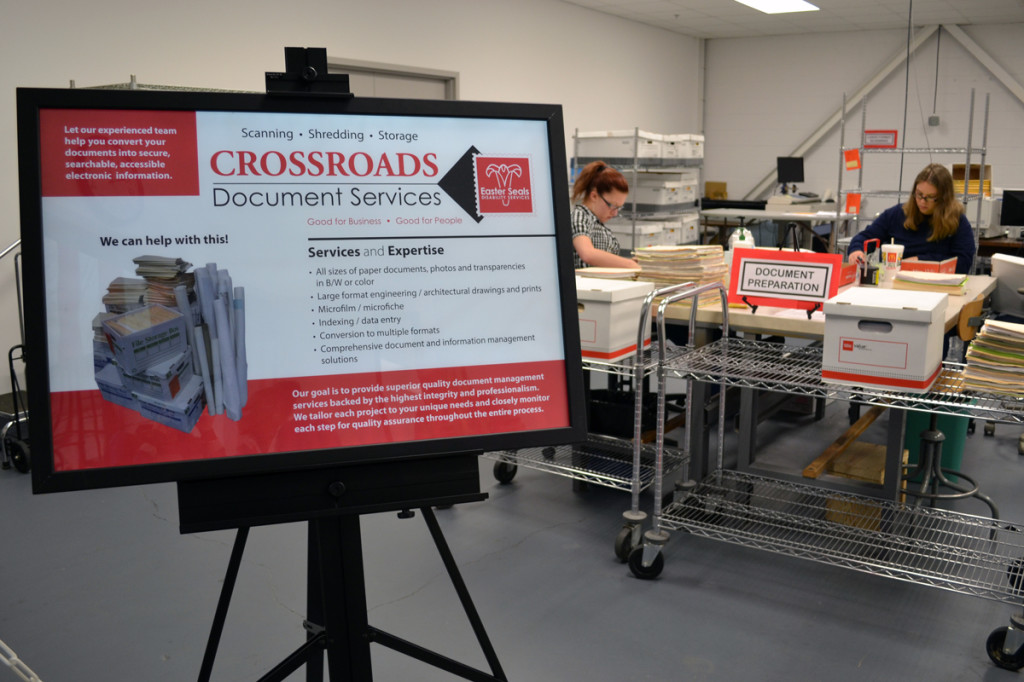

Document Scanning: Do-It-Yourself vs. Outsourcing

Today’s post was written by Mary Jo Gremling, Manager of Crossroads Document Services.

Are you weighing the pros and cons of tackling that document scanning project in-house? It can certainly be done, but such a venture requires a lot of thought, planning, and consideration to assure success without disrupting your entire office environment in the process.

Document scanning, while not “rocket science,” does require proper training and quality control to produce suitable electronic images. Remember, there is no room for mistakes—an error rate of even 0.1% means that one page in every 1,000 could be missing or unreadable, and that is totally unacceptable. Likewise, data entry must be accurate to ensure the record can be located and accessed after it has been scanned.

The Challenge of Do-It-Yourself Document Scanning

Using in-house staff to prepare and scan paper documents is one option to consider. This can be successfully performed with the understanding that the project will require at least two full-time employees (one to prepare the files and one to scan) as well as a workspace large enough to allow an efficient assembly-line process.

It is very important to carefully choose personnel for this project. Not everyone is detail-oriented enough to perform the repetitive, tedious task of removing staples and organizing pages. Nor does everyone recognize the importance of consistently capturing every piece of information in the file. Every scanned image should be viewed, checked against the original, and approved.

Your project will also require the use of a scanner fast enough to handle several thousand pages per day. While office scanners rated at 20-30 images per minute may work well on a go-forward basis, they are not robust enough to efficiently handle the initial work of scanning a large volume of documents. Whatever savings there may be in purchasing an inadequate scanner will be lost in the hours it will take to complete the project.

The scanner should have built-in fail-safe features to guard against more than one page feeding through at a time, resulting in lost information. Scanning software must allow images to be scanned into multiple-page PDF or TIFF files that can be named in an organized, logical structure.

Be aware that all imaging software does not produce the same results. Some have more file compression capabilities than others. Electronic file size can be an issue whether a business stores data internally on a server or uses a web-hosted system. Web-hosted services usually charge for data storage based on the total number of gigabytes used. The software provided with a multi-function machine (copier/scanner/fax) is not usually designed with this in mind.

Outsourcing: A Viable Alternative

While the do-it-yourself option may sound a bit overwhelming, there are more efficient ways to convert documents from paper to digital, decreasing the overall time required to complete the project and greatly reducing the stress on your office staff. One such option is outsourcing the scanning of paper records to an imaging service bureau.

An imaging service operates under a confidentiality agreement with each of its clients. All personnel who handle customer documents sign confidentiality agreements, and privacy requirements are strictly enforced. Records are usually transported to the service provider’s facility for processing.

At Crossroads Document Services, we have a fleet of vehicles for picking up any size shipment, from just a few boxes to many pallets of boxed or crated documents. We can also send our personnel to pack your files. We can even provide boxes!

In a production scanning environment, a dedicated team efficiently removes all staples and paper clips, positions sticky notes, unfolds, smoothes and aligns all pages. Trained scanner operators using high-speed equipment evaluate every image on the computer screen as each page is scanned. Quality control steps are built into each process to ensure all images are legibly captured and correctly labeled.

Outsourcing the scanning of business records to a competent imaging service should be seriously considered when weighing the transition from paper files to digital. The actual cost of outsourced scanning is often significantly less than the expenditure of purchasing adequate equipment and utilizing staff to perform the work in house.

An imaging service specializes in performing the “grunt work” associated with scanning and can have all records prepared, scanned, indexed, and uploaded in a fraction of the time it takes for persons with little or no experience in scanning large volumes of documents.

Having all records digitized at one time can streamline the implementation of electronic records management, allowing your organization to make the transition without the confusion created by having some files in paper and others electronic for an extended period of time.

Conclusion

While the transition to electronic records is a major paradigm shift requiring buy-in from your entire staff, it can be accomplished far more easily if day-to-day operations are allowed to proceed as usual, with as little disruption as possible. Outsourcing document preparation, scanning, and indexing to a service that specializes in these tasks eliminates the need to distract staff from their usual responsibilities. The end result is a smoother, less stressful transition and quicker implementation, at a price that is often less than the cost of using your own employees to perform the project.

Call Crossroads Document Services at 317-897-7320, ext. 4230 to discuss your imaging project. We take the pain out of going paperless!

Mary Jo owned and operated eLucida Imaging from 2003 to 2013, when her Indianapolis-based company was purchased by Crossroads Industrial Services. She now manages Crossroads Document Services, located at 8302 E. 33rd Street, Indianapolis, IN 46226.

The Benefits of Outsourced Manufacturing

Today’s post was written by Curtiss Quirin, Chief Operating Officer of Crossroads Industrial Services.

Outsourcing manufacturing can be a matter of convenience for small and mid-size companies, but it can also be a great way to do business. With the ability to outsource their manufacturing to a competent contract manufacturer, companies can gain the economies of scale, flexibility and resources that allow them to effectively compete with their larger competitors. It will also allow them to focus their time and limited resources on product development, sales and marketing.

If you are a smaller company, you will face challenges that require resources greater than your larger competitors. The decision for you, the original equipment manufacturer, is to make the right contract manufacturer selection, and partner with them to establish a relationship as an extension of your business. The goal is to negotiate win/win pricing and contract terms, and invest time and resources to develop relationship an ongoing collaborative relationship.

Lucky for you, Crossroads Industrial Services can do just that. For more information, view our page on Supply Chain Services to understand our process from procurement and manufacturing to sales.